Innovation and a focus on all stakeholders is key to GinnDesign’s success.

Tight integration and collaboration with the client allow us to bring products to the market quickly and cost-effectively while remaining mindful of the needs of all stakeholders. From the User to the manufacturer, we discover unmet needs while developing new and improved product features that are essential to differentiating products in today’s competitive market.

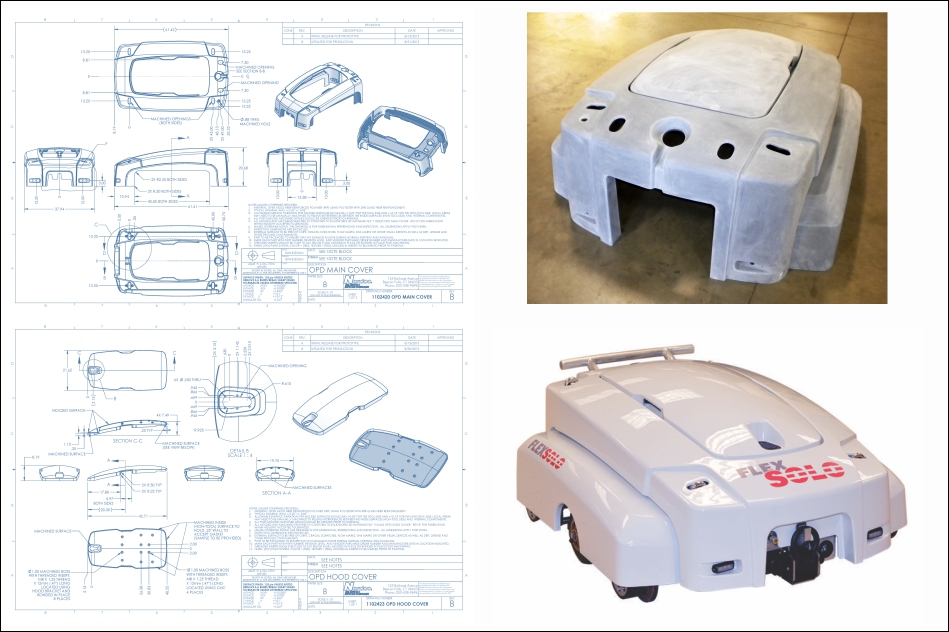

GinnDesign has extensive experience in developing the complete physical enclosure design and assembly methodology for many types of products. Typically, the client develops the core technology and we create the industrial design and engineering for the overall system packaging through tooling release and early production. We also develop complete products where the internal technology is already resolved and industrial design is the differentiating factor.

Full-Service Turnkey Product Development

- Integrated Product Development Services

- Product Concept Development to Design for Production

- Industrial Design and Product Styling

- Form and Brand Language Development

- Strategic and Tactical Collaboration and Support

Value-Added Design Support for In-House Design Staff and Manufacturers

- Expand Your In-House Design Staff Capabilities

- Collaboration with In-house Designers and Engineers for a Fresh Perspective

- Expanded Design Support Beyond Part Design

- Combine In-house Manufacturing with Other Processes

Complete Production Assembly Design and Part Engineering

- Convert Concept Sketches into a Manufacturable Product

- Plastic and Metal Part Design and Detailing

- Assembly Process Design and Development

- Final Production Database Documentation and Support

Product Methodizing and Manufacturing Consulting

- Product Design Audit, Review, and Analysis

- Vendor Identification and Qualification

- Liaison between Clients, Vendors, and Suppliers

- Production Startup Support and Troubleshooting

Materials and Processes

We specialize in design for low-to-medium volume production where the materials and manufacturing processes can be more challenging. A typical project might involve lower production quantities, functional or material constraints or large physical size and/or complexity that make traditional injection molding prohibitively expensive, complex or time-consuming. There are many alternatives available that can meet your challenge; the key is knowing someone who has experience working with these alternative processes.

Manufacturing Processes:

- Rapid Injection Molding

- Low-Pressure Structural Foam

- Extrusion

- Blow Molding

- Rotational Molding

- Thermoforming

- Reaction Injection Molding (RIM)

- Resin Transfer Molding (RTM)

- SMC and BMC

- Casting (Metal and Urethane)

- Sheet Metal Fabrication

- Tubing Fabrication

- Metal Stamping, Forming and Weldments

- Rapid Prototyping

- Custom Plastic and Metal Machining and Fabrication

- Assembly and Finishing Processes

The Deliverables…

Typical deliverables can include:

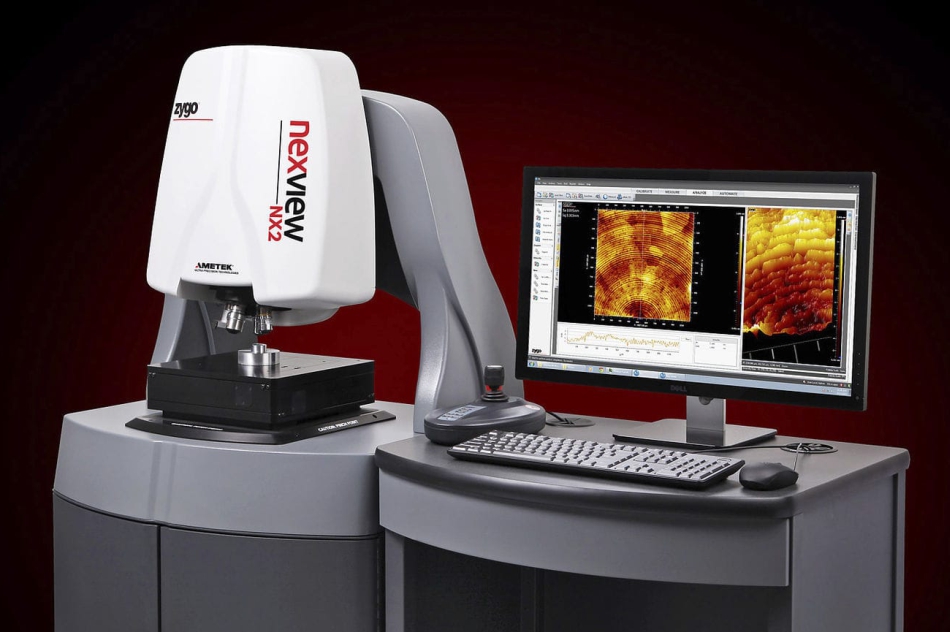

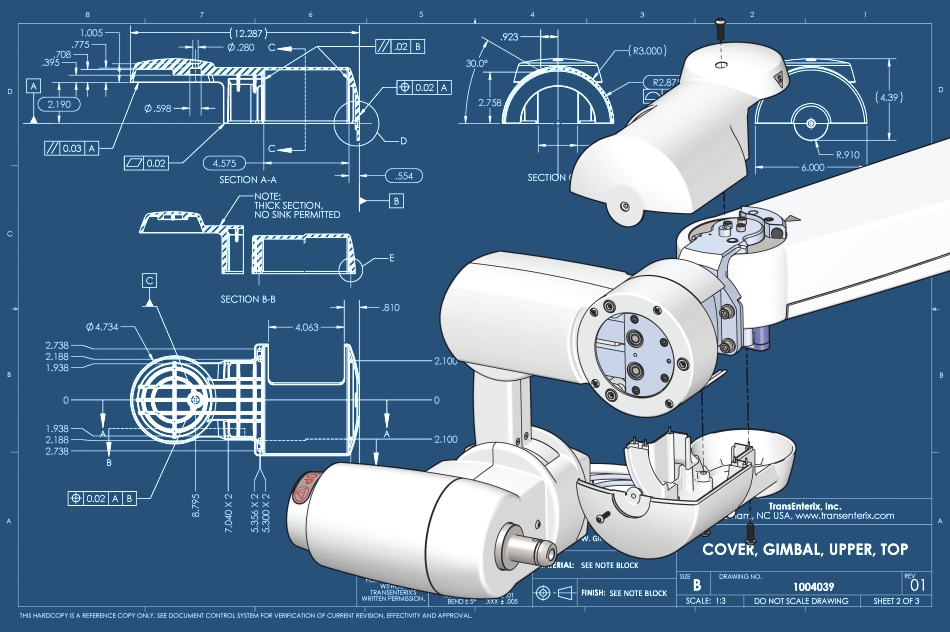

- Complete production 3D database developed in SolidWorks.

- Detailed 3D part and assembly design and production files.

- Completely detailed and toleranced 2D production drawings.

- Bill of Materials with assembly drawings.

- Additional product specifications and documentation.

Large volumes of work can be produced professionally, efficiently, on schedule, within budget and always with careful attention to detail.

Additional deliverables can include:

- Product Graphics (logos and badging) and Production Files

- Detailed Illustrations for Presentations

- Production Assembly Diagrams

- Patent Drawings

- Product User Manuals

- Color Renderings For use in Sales Brochures